“Microsoft vs Google”

Microsoft and Google are two of the biggest tech companies in the world, competing in various markets such as cloud computing, productivity software, search engines, and online advertising. In this blog post, we will compare the performance of these two giants in some of their key segments and see how Microsoft is gaining an edge over Google.

Table of Contents

ToggleMicrosoft vs Google in Cloud Computing: An Overview

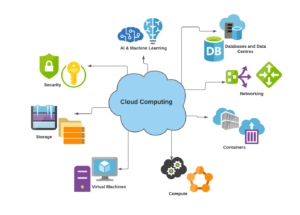

Cloud computing is one of the fastest-growing and most lucrative segments in the tech industry, as more businesses and organizations migrate their data and applications to the cloud. According to Synergy Research Group, the global cloud market grew by 39% year-over-year in Q3 2023, reaching $65 billion in quarterly revenues.

Among the top cloud providers, Microsoft is the second-largest after Amazon Web Services (AWS), with a 23% market share in Q3 2023, up from 21% a year ago. Google Cloud is the third-largest, with a 10% market share, up from 9% a year ago . While both Microsoft and Google are growing faster than AWS, Microsoft is expanding its lead over Google in terms of revenue and market share.

One of the reasons why Microsoft is outperforming Google in the cloud market is its strong presence in the enterprise segment, where it leverages its existing relationships with customers who use its software products such as Windows, Office, and Dynamics. Microsoft also offers a hybrid cloud solution called Azure Stack, which allows customers to run their applications on-premises or in the cloud with consistent tools and services. Google, on the other hand, is more focused on the consumer segment, where it faces stiff competition from AWS and other players such as Alibaba and Tencent.

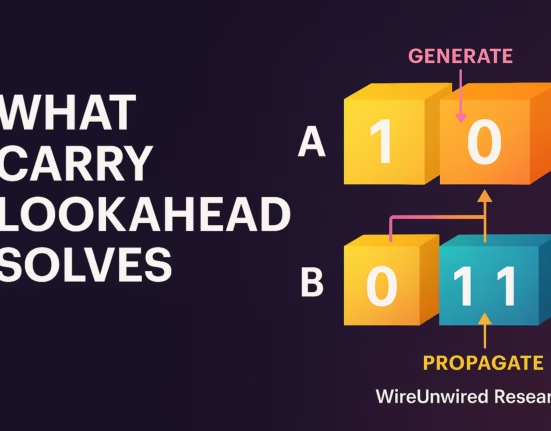

Another reason why Microsoft is beating Google in the cloud market is its investment in artificial intelligence (AI) and machine learning (ML), which are key drivers of innovation and differentiation in the cloud space. Microsoft has been developing and acquiring AI and ML capabilities for years, such as Cortana, Azure Cognitive Services, GitHub Copilot, Nuance Communications, and OpenAI. These technologies enable Microsoft to offer more value-added services to its cloud customers, such as speech recognition, natural language processing, computer vision, and conversational AI. Google also has a strong AI and ML portfolio, such as Google Assistant, TensorFlow, Cloud AI Platform, and DeepMind, but it has not been able to translate them into significant revenue growth or market share gains.

5 Technologies of 2024 that you should must know.

Productivity Software

Productivity software is another important segment where Microsoft and Google compete head-to-head. Both companies offer suites of applications that enable users to create, edit, share, and collaborate on documents, spreadsheets, presentations, emails, calendars, and more. Microsoft’s suite is called Microsoft 365 (formerly Office 365), while Google’s suite is called Google Workspace (formerly G Suite).

According to Statista, Microsoft 365 had a 48.08% share of the global productivity software market as of November 2022, while Google Workspace had a 46.44% share . However, these numbers do not reflect the revenue or profitability of each suite, which are likely to be much higher for Microsoft than for Google.

One of the reasons why Microsoft has an advantage over Google in the productivity software market is its legacy and familiarity among users who have been using its applications for decades. Microsoft’s applications are widely regarded as the industry standards for word processing (Word), spreadsheet (Excel), presentation (PowerPoint), email (Outlook), and collaboration (Teams). Google’s applications are relatively newer and less feature-rich than Microsoft’s, although they have gained popularity among users who prefer web-based and mobile-friendly solutions.

Another reason why Microsoft is ahead of Google in the productivity software market is its integration and interoperability with its other products and services. For example, Microsoft 365 users can easily access their files and data from OneDrive or SharePoint Online; use AI-powered features such as Editor or Designer; or connect with other apps such as Dynamics 365 or Power BI. Google Workspace users can also integrate with some of Google’s products and services, such as Gmail or Drive; use AI-powered features such as Smart Compose or Explore; or connect with other apps such as YouTube or Maps. However, Microsoft’s ecosystem is more comprehensive and cohesive than Google’s.

Search Engines

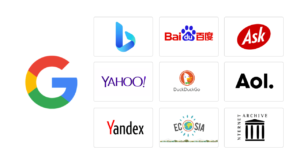

Search engines are perhaps the most well-known segment where Microsoft and Google compete directly. Both companies operate online platforms that allow users to find information on the web by entering keywords or queries. Microsoft’s search engine is called Bing , while Google’s search engine is called Google.

According to Statista, Google had an 83.49% share of the global desktop search engine market as of July 2023, while Bing had a 9.19% share. However, these numbers do not include mobile searches. which will likely be much higher for Google than for Bing.

One of the reasons why Google dominates the search engine market is its superior technology and algorithm, which deliver fast and relevant results to users. Google also has strong brand recognition and loyalty among users, who often use Google as a verb to mean searching on the web. Google also offers a variety of features and services that enhance the user experience, such as Google Images, Google Maps, Google News, Google Shopping, and Google Assistant.

Another reason why Google beats Microsoft in the search engine market is its diversified and profitable advertising business, which generates most of its revenue and profit. Google operates two main advertising platforms: Google Ads, which allows advertisers to display ads on Google’s properties and partner sites; and Google AdSense, which allows publishers to display ads on their websites and earn revenue from clicks or impressions. Microsoft also operates an advertising platform called Microsoft Advertising, which allows advertisers to display ads on Bing and other Microsoft properties and partner sites. However, Microsoft’s advertising revenue and market share are much lower than Google’s.

Microsoft hit the mark of 3trillion Market cap..

Microsoft is outperforming Google in the cloud computing market, where it leverages its strong enterprise presence, hybrid cloud solution, and AI and ML capabilities. Microsoft is also ahead of Google in the productivity software market, where it benefits from its legacy and familiarity among users, as well as its integration and interoperability with its other products and services. However, Google dominates the search engine market, where it has superior technology and algorithm, strong brand recognition and loyalty among users, and diversified and profitable advertising.

- Carry Lookahead Adders Explained: Why Tree-Based Logic Powers Modern CPUs ?

- What Is AMBA? A Simple Guide to Advanced Microcontroller Bus Architecture for SoC Designers

- How Wind Turbines Deliver Stable 50Hz Power at variable Wind Speed?

- Disney vs Midjourney Lawsuit Could Redefine Generative AI: Wireunwired Report

- Nvidia’s $4.5B Lesson to Every Hardware Company: You Can’t Out-Innovate Sanctions

In conclusion , Microsoft and Google are two of the most successful and influential tech companies in the world , competing in various markets such as cloud computing , productivity software , search engines , and online advertising . In this blog post , we have compared the performance of these two giants in some of their key segments and seen how Microsoft is gaining an edge over Google.

Both companies are constantly innovating and expanding their offerings to capture new opportunities and challenges in the tech industry. Therefore , it will be interesting to see how they will continue to compete and cooperate in the future.

Discover more from WireUnwired

Subscribe to get the latest posts sent to your email.