The Rising Demand for Rare Earth Metals

With the demand for cleaner and more sustainable technologies on the rise, the shortage of some essential materials, known as Rare Earth Metal, created a surge for looking into rare earth metal Alternatives,which has prompted researchers and manufacturers to explore different solutions.

This shift towards innovation not only addresses the immediate supply chain challenges but also accelerates the global transition towards cleaner and greener energy sources. indeed these metals are not rare in earth but their demand in the industry is increasing day by day as compare to their rate of production. Tesla has also stated that it plans to phase out rare earth metals.

What are Rare Earth Metals?

Before we further go into the discussion of Rare Earth Metals Alternatives, let’s discuss what is a rare earth metal.

Don’t go by the names They are not rare in the sense of being scarce, but they are difficult to extract and refine from the earth’s crust.,that’s why these metals are termed rare metals. These are a group of 17 metals that are quite abundant in nature but are evenly distributed across the earth, i.e. these metals are not in bulk in a particular area instead they are in some quantity everywhere across the earth, this even distribution makes it difficult to extract.

The Role of Rare Earth Metals in Industry

One thing to note about these rare earth metals is that these rare earth metals play a very crucial role in making high-quality magnets, again which are very crucial parts of some rapidly growing industries like electric vehicle (EV) and renewable energy sectors.

The supply of some rare earth chemical elements will need to increase sevenfold by 2050 just to meet the demand for wind turbines. Demand for rare earth metals such as neodymium and dysprosium for electric vehicles could increase 15-fold by 2040.

Rare earth metals, including neodymium, dysprosium, and praseodymium, play a pivotal role in the production of powerful magnets used in electric motors and generators. These magnets are crucial components in EVs, wind turbines, and various other green technologies. However, the global supply chain for these materials is dominated by a few countries, primarily China, leading to concerns about the security and stability of the supply.

In recent years, geopolitical tensions and trade disputes have highlighted the vulnerability of the rare earth supply chain. As a result, the industry is facing a growing urgency to find alternative solutions to reduce dependence on a handful of suppliers and secure a sustainable source of these critical materials.

Looking for Rare Earth Metals Alternatives

Now let’s quickly see what are the problems that the shortage of rare earth metals will produce and how Tesla is dealing with this.

So the companies have started looking out for rare earth metals alteratives and have started Developing new magnet materials that do not depend on rare earth elements, such as iron, cobalt, and nickel. These materials are more abundant and accessible than rare earth elements, and can produce strong and stable magnetic fields.

Recycling rare earth materials from existing electronic devices and industrial waste. This approach not only reduces the demand for new rare earth materials, but also minimizes the environmental impact of mining and processing them.

- Inside AXI: The Invisible Backbone of AI Accelerators

- Carry Lookahead Adders Explained: Why Tree-Based Logic Powers Modern CPUs ?

- What Is AMBA? A Simple Guide to Advanced Microcontroller Bus Architecture for SoC Designers

- How Wind Turbines Deliver Stable 50Hz Power at variable Wind Speed?

- Disney vs Midjourney Lawsuit Could Redefine Generative AI: Wireunwired Report

How Tesla is dealing with this?

Tesla has started working on building magnets made of alternatives of rare earth metals . It’s in news that they have started using Iron Nitride as an alternative to these rare earth metals.

Also it seems that they are in talks with They are building a production facility for iron nitride, which is derived from common elements, to address potential future shortages. It aims to reach a production capacity of 1,000 kilograms by the end of 2024.

Rare Earth Metal Alternatives found

Neomagnets are a specific type of magnet that does not use rare earth elements. They are made of neodymium, iron, and boronelements that are relatively common and inexpensive. Neomagnets have similar magnetic properties to rare earth magnets, making them a suitable alternative for many applications.

Inside AXI: The Invisible Backbone of AI Accelerators

Explore how the AXI protocol powers modern AI accelerators by enabling high-throughput, low-latency data transfers across chips, cores, and memory.

- by Abhinav Kumar

- 9 July 2025

Carry Lookahead Adders Explained: Why Tree-Based Logic Powers Modern CPUs ?

Carry lookahead adders solve the delay problem in ripple-carry designs by predicting carry signals in advance. This article breaks down.

- by Abhinav Kumar

- 23 June 2025

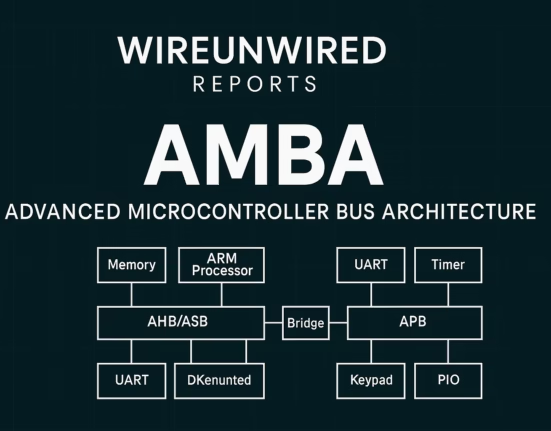

What Is AMBA? A Simple Guide to Advanced Microcontroller Bus Architecture for SoC Designers

Learn how AMBA (Advanced Microcontroller Bus Architecture) powers communication inside modern SoCs. From APB to AHB and AXI, explore the.

- by Abhinav Kumar

- 22 June 2025

Discover more from WireUnwired

Subscribe to get the latest posts sent to your email.

2 Comments