The Environmental Cost of Chip Production: Numbers will shock you

The way Nvidia’s market cap has risen in the past 1 to 2 years has led everyone to talk about semiconductor companies as the next big thing. I think everyone should actually be talking about these semiconductor companies, as they are the ones powering all our modern day devices. They are truly the backbone of our technological world.

But have you ever thought about what we are paying for the manufacturing of these semiconductor chips? I am not talking about the cost of the devices themselves, but rather the environmental and social costs associated with their production.

In this article, we will try to decode the environmental cost of chip production. Understanding the environmental impact of chip production is crucial as the demand for semiconductors continues to rise.

Raw material extraction is the first step towards semiconductor manufacturing , so let us start our discussion of the environmental cost of chip production with the environmental impact of raw material extraction only.

Also Read : Semiconductor Manufacturing 101

Table of Contents

ToggleEnvironmental Impact of Raw Material Extraction

The production of semiconductor chips begins with the extraction of raw materials, primarily silicon. This process involves mining and refining, which are energy-intensive and often result in significant environmental degradation. For example, extracting and processing silicon and rare earth metals leads to deforestation, soil erosion, and pollution of water sources with hazardous chemicals. The mining of these materials also emits substantial amounts of carbon dioxide (CO2) and other greenhouse gases (GHGs) (McKinsey & Company) (BCG Global).

For instance, a single ton of rare earth elements can produce up to 2,000 tons of toxic waste (McKinsey & Company) (BCG Global). Over the years, advancements in mining technology have increased efficiency, but they have also intensified environmental damage due to higher production volumes.

According to a research paper “Reducing the Carbon Footprint: Primary Production of Aluminum and Silicon with Changing Energy Systems” published in the Journal of Sustainable Metallurgy on average extraction of one ton Silicon produces 5 Kg of CO2.

Energy Consumption in Chip Manufacturing

Chip manufacturing is an extremely energy-intensive process. Semiconductor fabrication plants, or fabs, consume vast amounts of electricity to maintain the precise conditions required for chip production.

For instance, advanced fabs like those operated by TSMC and Intel consume thousands of gigawatt-hours (GWh) of electricity annually. This high energy demand contributes significantly to the carbon footprint of chip production. Most of this energy comes from non-renewable sources, further exacerbating the environmental impact (McKinsey & Company) (Tech Monitor).

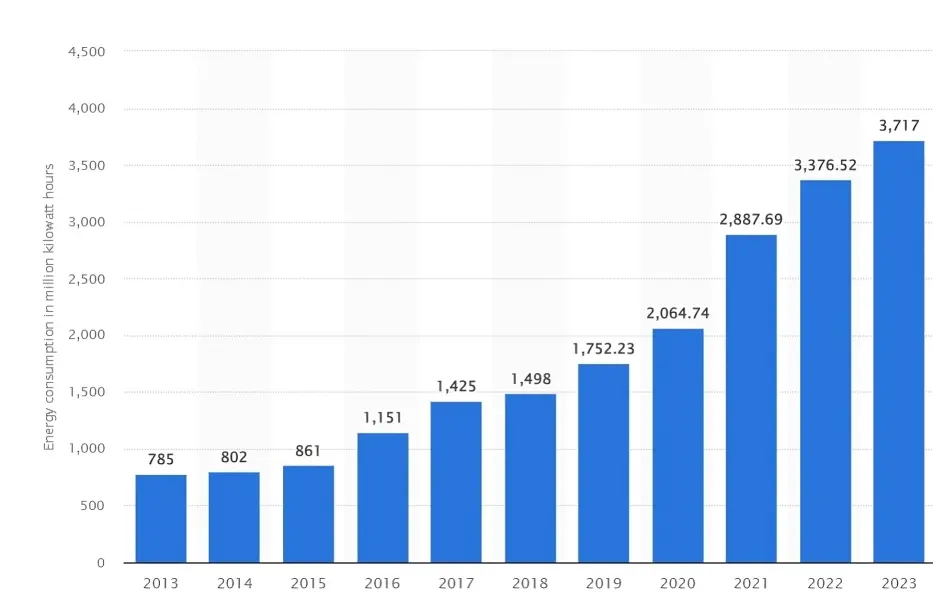

Further the energy demand has increased over the years to fulfil the needs. According to data given by Statista , alone the energy demand of SMIC has rose from 785 Mn KWH in 2013 to 3717 Mn KWH in 2023 , given that SMIC does not manufacture that much semiconductors as compared to TSMC and Intel , one can imagine how the energy demand for TSMC and Intel would have increased.

Also Read : 2 nm chip race is heating up , who will win Intel or TSMC?

Water Usage in Chip Production

The semiconductor industry is a heavy user of water, essential for the production process and for maintaining cleanroom environments. For instance, TSMC’s facilities in Taiwan consume significant volumes of water daily.

According to ISB Blogs A semiconductor manufacturing facility may require over five million gallons of UPW daily. To produce this pure water, at least eight million gallons of city water daily are needed. Efforts are being made to treat and recycle wastewater, but the overall water footprint remains substantial. This is particularly concerning in regions experiencing water scarcity (Tech Monitor)

Waste and Pollution

The manufacturing process generates a variety of wastes, including hazardous chemicals and gases. For every single silicon wafer produced, large quantities of bulk gases, hazardous gases, deionized water, and chemicals are used, leading to substantial waste production. The improper disposal of these wastes can lead to soil and water contamination, posing serious environmental and health risks (BCG Global).

Sustainable Practices and Innovations

Despite the challenges, the semiconductor industry is making efforts to mitigate its environmental impact. Companies like TSMC, Intel, and Samsung are investing in technologies to reduce water usage and improve recycling processes.

For instance, TSMC is building a plant to treat industrial wastewater for reuse, potentially meeting up to 50% of its daily water needs (Tech Monitor). Additionally, there are ongoing efforts to reduce energy consumption through the use of more efficient tools and renewable energy sources. Innovations such as green chemistries and more efficient manufacturing processes are also being explored to lower emissions and reduce the environmental footprint of chip production (McKinsey & Company) (Tech Monitor).

Conclusion

The production of semiconductor chips is crucial for modern technology but comes with significant environmental costs. From raw material extraction to energy consumption and waste production, the industry faces numerous challenges. However, through sustainable practices and innovative technologies, the semiconductor industry can reduce its environmental impact and move towards a more sustainable future. For more detailed insights and updates on sustainability in the semiconductor industry, you can visit WireUnwired.

Editor’s choice

Discover more from WireUnwired

Subscribe to get the latest posts sent to your email.