Three phase induction motors can be classified into two categories: squirrel cage motor and slip ring motor. These motors have different starting methods, which we will discuss below.

Starting Methods for Squirrel Cage Induction Motor

The following four methods are available for starting squirrel cage motors −

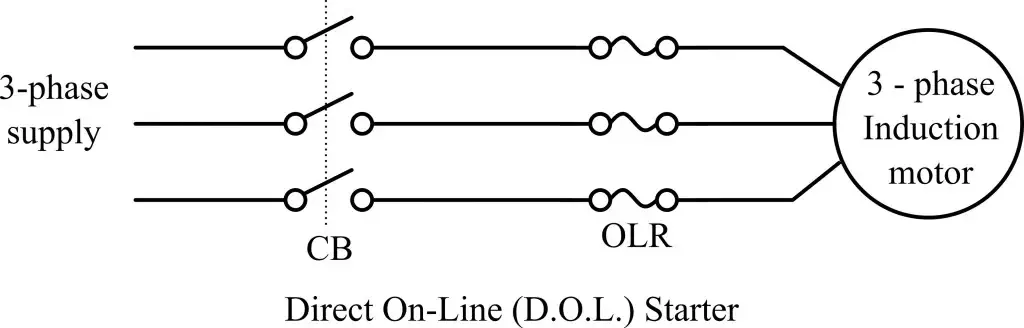

Direct On-Line (D.O.L.) Starting

This method of starting an induction motor involves connecting it directly to the three-phase supply without any intermediate device. The main drawback of this method is that it causes a high inrush current (about 4 to 7 times of the normal current) and a low power factor. Therefore, this method is only recommended for small motors (up to 10 kW) that do not cause significant voltage drop or disturbance in the supply system. The following diagram shows the DOL starting circuit for an induction motor.

The high inrush current and low power factor affect the efficiency of the induction motor in two ways. First, they increase the power losses in the motor windings and the supply lines, which reduces the output power of the motor. Second, they lower the voltage at the motor terminals, which reduces the torque and speed of the motor. Therefore, DOL starting reduces the efficiency of the induction motor compared to other methods that limit the starting current and improve the power factor.

Stator Resistance Starting

This method involves connecting an external resistance in series with each phase of the stator winding when the motor starts. The external resistance causes a voltage drop across it, which reduces the voltage available at the motor terminals. This lowers the starting current. The external resistances are gradually removed in steps from the stator circuit as the motor speeds up. When the motor reaches the rated speed, the external resistances are completely removed and the full line voltage is applied to the motor terminals.

This method has some disadvantages. First, the lower voltage during starting reduces the starting torque and hence increases the time to accelerate. Second, a lot of power is wasted in the external resistances.

Autotransformer Starting

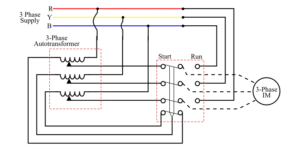

One way to start an induction motor with a reduced voltage is to use an autotransformer. An autotransformer has different tapings that can adjust the voltage applied to the motor during starting. By using an autotransformer, the motor can start with 60 to 80 % of the line voltage and then switch to the full-line voltage when it reaches a high enough speed.

The process is as follows: When the motor is started, the switch is in the ‘Start’ position. This connects the motor to the autotransformer, which lowers the voltage and limits the starting current. When the motor reaches about 80% of its rated speed, the switch is moved to the ‘Run’ position. This disconnects the autotransformer and applies the full line voltage to the motor terminals.

The advantage of using an autotransformer is that it reduces the power loss and the starting current of the motor. This method is suitable for large motors over 25 hp.

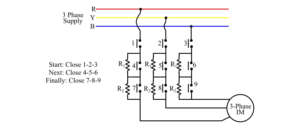

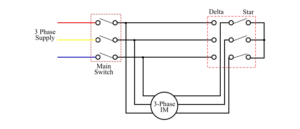

Star-Delta Starting

This is a method of starting a squirrel cage induction motor, where the motor is initially connected in star and then switched to delta after reaching a certain speed. The stator winding of the motor is designed to operate in delta, but it is temporarily connected in star by a change-over switch during the starting period. This way, the voltage across each phase is reduced by a factor of √3, which also reduces the starting current. When the motor reaches about 80% of its rated speed, the change-over switch is moved to delta, which restores the full line voltage to each phase.

The main drawback of this method is that the starting torque is also reduced by a factor of √3 due to the lower voltage in star connection. Therefore, this method is suitable for medium size motors up to 25 hp that do not require high starting torque.

Slip Ring Induction Motor Starting Methods

A slip ring induction motor can be started by four different methods, namely:

– Direct On-Line (D.O.L.) Starting

– Stator-Resistance Starting

– Autotransformer Starting

– Rotor-Resistance Starting

The first three methods are similar to those used for starting a squirrel cage induction motor, as explained in the previous section. The fourth method, which is the most common one for industrial applications, involves inserting resistors in the rotor circuit to reduce the starting current and increase the starting torque. The resistors are gradually cut out as the motor accelerates, until the rotor terminals are short-circuited.

Rotor Resistance Starting

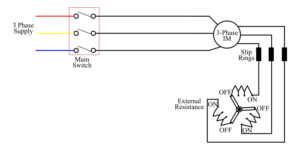

The rotor resistance starting method involves connecting a variable star-connected resistance to the rotor circuit via slip-rings. The stator windings receive the full voltage.

When the motor starts, the rheostat handle is in the ‘OFF’ position, which adds maximum resistance to each phase of the rotor circuit. This lowers the starting current and increases the starting torque due to the external rotor resistance.

The external resistance is gradually reduced from the rotor circuit as the motor speeds up. When the motor reaches the rated speed, the handle is switched to the ‘ON’ position, which eliminates all the external resistance from the rotor circuit.

Recommended Books :

1.Electrical Machine by Dr. P. S. Bhimbra (Highly Recommended for GATE / IES)

2. Electric Machines by Ashfaq Husain and Harroon Ashfaq

3. Electric Machinery Fundamentals by Stephen Chapman

Some Related articles:

Why Python is the best Choice for Programmers Working in AI Field ?

Dawn of New era:Generative AI in Data Science

Discover more from WireUnwired Research

Subscribe to get the latest posts sent to your email.