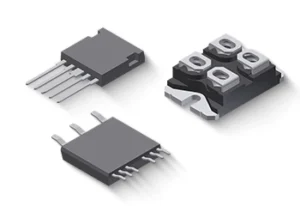

In the pursuit of a sustainable automotive future, the electric vehicle (EV) revolution is underway. This transformation is deeply rooted in materials science, with a particular focus on the remarkable properties of silicon carbide (SiC). SiC, a compound of silicon and carbon, is emerging as a transformative force in elevating the performance of electric vehicles. Its unique attributes are reshaping the landscape of power electronics and electric propulsion systems.

Silicon Carbide: Paving the Way for EV Advancements:

Silicon carbide’s journey from laboratories to the forefront of electric vehicle technology is marked by its exceptional characteristics. With a wide bandgap, high thermal conductivity, and superior electrical properties, SiC has become a cornerstone material in power electronics applications, fostering advancements in EV technology.

Key Features of Silicon Carbide (SiC):

Enhanced Power Conversion Efficiency in Electric Vehicles:

The defining feature of SiC is its wide bandgap, surpassing traditional silicon-based semiconductors. This characteristic, coupled with lower switching and conduction losses during power conversion, leads to a substantial boost in power conversion efficiency. This improvement is pivotal for maximizing energy usage in electric vehicles and enhancing their overall performance.

Elevated Temperature Tolerance for Optimal EV Operation:

As electric vehicles generate significant heat during operation, materials with elevated temperature tolerance are essential. Silicon carbide’s impressive thermal conductivity and high-temperature tolerance make it the ideal choice for power electronics. This not only ensures efficient operation but also enables the design of compact and lightweight cooling systems, contributing to the longevity of EV components.

Streamlined Power Electronics for Lightweight EVs:

SiC’s efficiency gains, combined with its resilience to high temperatures, enable a reduction in the size and weight of power electronics components. In the electric vehicle sector, where weight directly impacts energy efficiency and driving range, SiC facilitates the creation of compact and lightweight components without compromising performance.

Reliability and Durability: SiC’s Contribution to Long-Lasting EVs:

Silicon carbide’s robust nature significantly enhances the reliability and durability of power electronics in electric vehicles. With the ability to withstand higher voltages and temperatures, SiC-based components exhibit a longer operational lifespan, reducing maintenance costs and enhancing the economic viability of electric vehicles.

Accelerating Fast-Charging Capabilities in Electric Vehicles:

SiC’s efficiency gains extend to fast-charging technologies, addressing a major concern for prospective EV adopters – charging time. Reduced losses in SiC-based power electronics enable faster charging rates, propelling the electric vehicle charging infrastructure towards quicker and more efficient replenishment.

Conclusion:

Silicon carbide, positioned as a beacon of innovation in materials science, is spearheading the transformation of electric vehicle technology. Its unparalleled combination of thermal, electrical, and mechanical properties empowers engineers and researchers to transcend traditional limitations in power electronics. As the automotive industry accelerates towards electrification, silicon carbide stands poised to revolutionize the efficiency, reliability, and overall performance of electric vehicles. In this relentless pursuit, SiC emerges not just as a technological marvel but as a driving force propelling the world towards a more sustainable and greener transportation future. Embracing SiC in electric vehicles signifies a harmonious blend of environmental friendliness with practicality and efficiency, shaping the future of automotive sustainability.

Discover more from WireUnwired Research

Subscribe to get the latest posts sent to your email.