High pressure heaters play a crucial role in enhancing the efficiency of thermal power plants by preheating boiler feedwater through regenerative heating. In this article, we’ll explore the stages of high pressure heaters, the impact of drip levels on temperature gains, and why maintaining optimal levels is essential for maximizing heat recovery and overall plant performance.

TRENDING

What Are High Pressure Heaters in Power Plants?

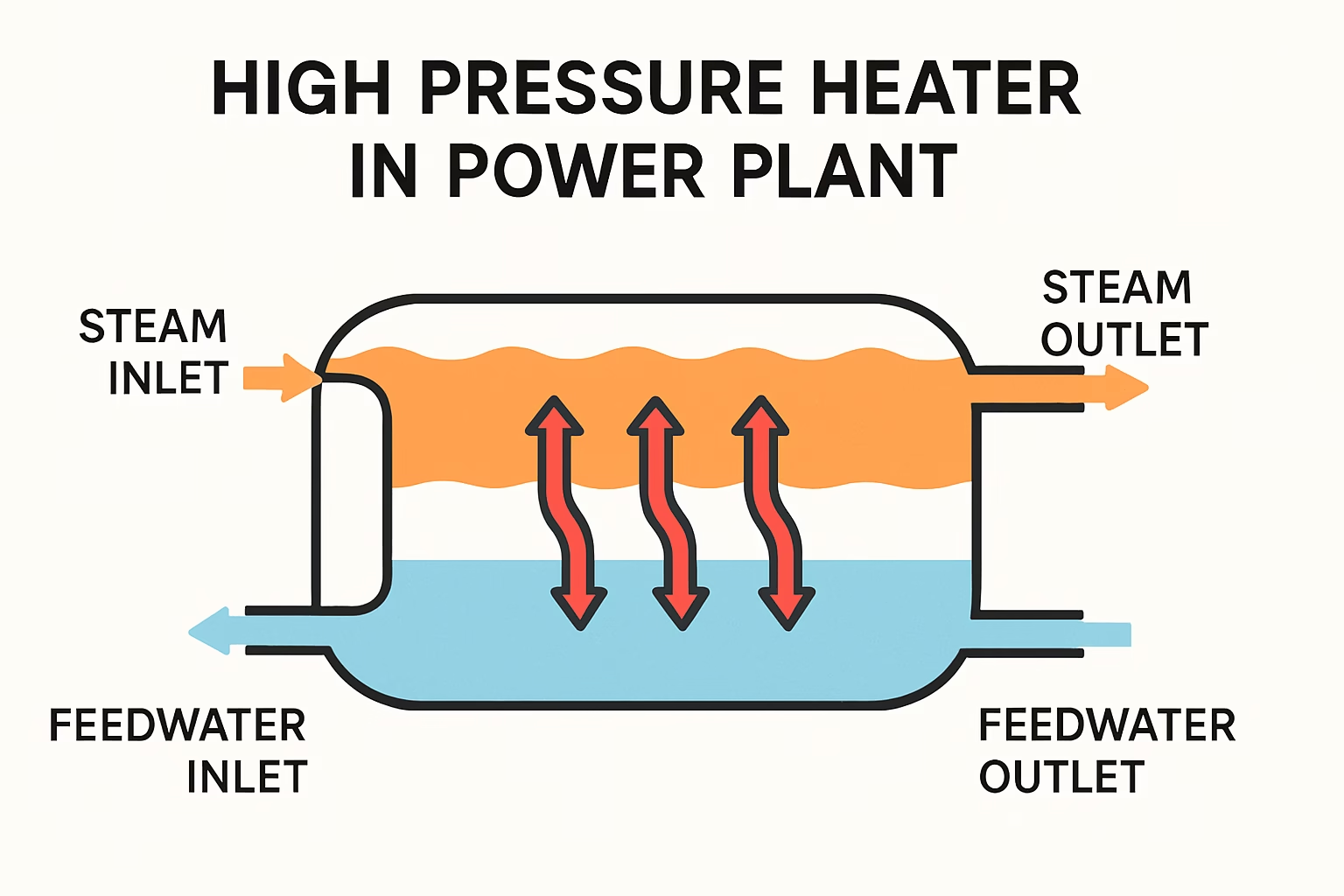

In thermal power plants, high pressure (HP) heaters are specialized shell-and-tube heat exchangers that use extraction steam from the turbine to preheat feedwater before it enters the boiler. This process, part of the regenerative Rankine cycle, improves thermal efficiency by recovering waste heat, reducing fuel consumption, and minimizing thermal stress on the boiler. Typically located after the boiler feed pump, HP heaters operate under pressures exceeding 100 kg/cm² and can raise feedwater temperature by 20-50°C per unit, contributing to a 5-10% efficiency boost in the power cycle.

These heaters are integral to the feedwater heating system, often arranged in series with low-pressure heaters. Extraction steam from the high-pressure turbine enters the shell side, while feedwater flows through the tubes, enabling efficient heat transfer without direct mixing

The Stages of High Pressure Heaters

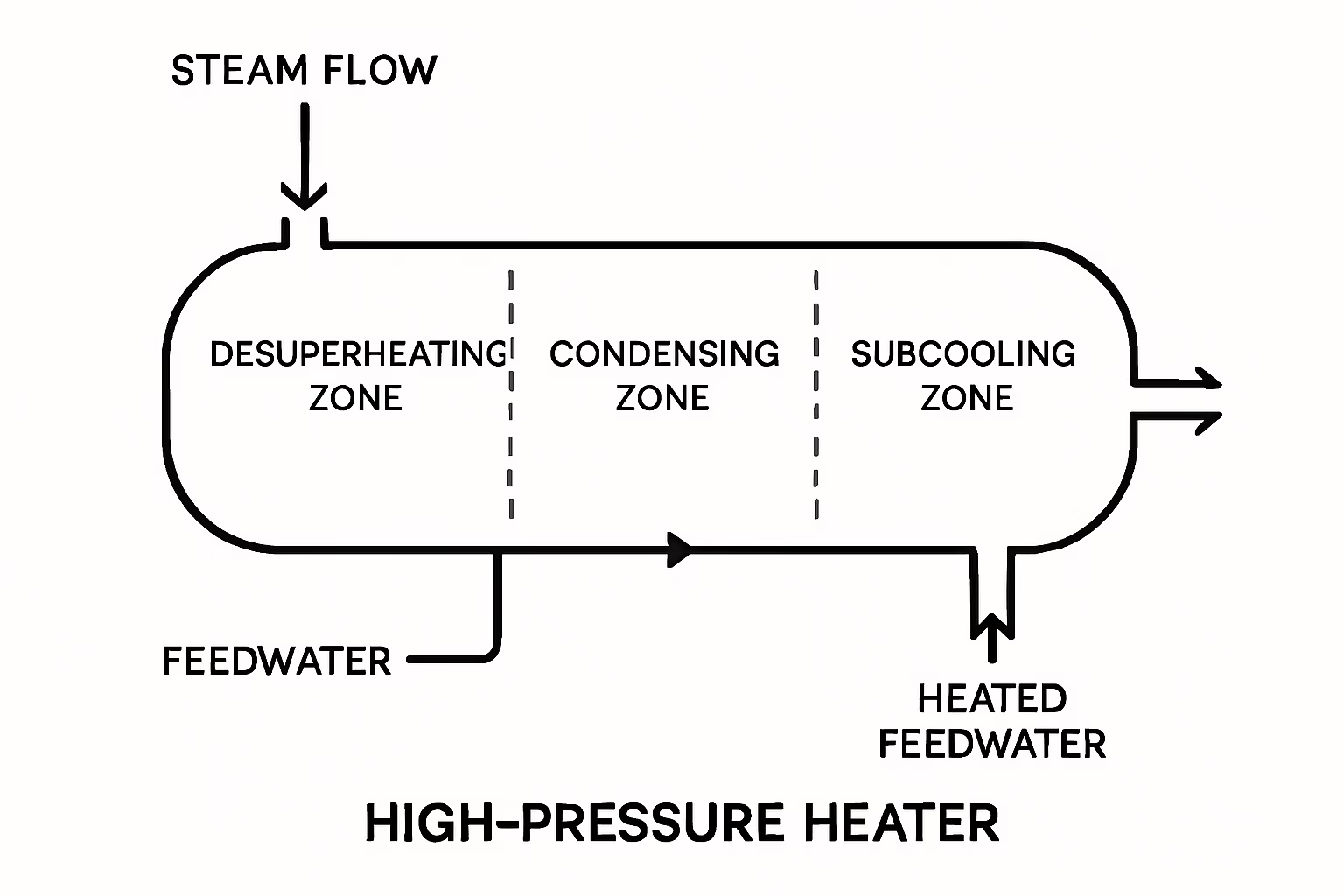

HP heaters are divided into three primary thermal zones or stages, each corresponding to a phase change in the extraction steam. This zoned design ensures progressive heat transfer, from superheated steam to subcooled condensate, optimizing energy recovery. The stages are typically arranged horizontally or vertically, with feedwater entering cold and exiting hot.

- Desuperheating Zone: This initial stage cools superheated steam from the turbine to its saturation temperature. Through convective heat transfer, the steam loses excess heat to the feedwater, preventing thermal shock and preparing it for condensation. It’s located near the steam inlet and is essential for handling high-temperature inputs.

- Condensing Zone: The core heat transfer area where saturated steam condenses into liquid condensate, releasing latent heat to the feedwater. This zone accounts for the majority of temperature gain, with non-condensable gases vented to maintain efficiency and avoid corrosion. Effective condensation here directly impacts the heater’s overall performance.

- Subcooling (Drain Cooling) Zone: In the final stage, the condensate is cooled below its saturation temperature by the incoming feedwater, recovering additional sensible heat. This subcooling prevents flashing in downstream systems and cascades drains to lower-pressure heaters or the deaerator, enhancing regenerative efficiency.

These stages work sequentially: steam enters as a superheated vapor, condenses, and exits as subcooled liquid, while feedwater gains heat progressively. In a typical setup, multiple HP heaters (e.g., HP Heater 1 and 2) are used, each tied to specific turbine extraction points for staged heating.

How Drip Levels Influence Temperature Gains in HP Heaters

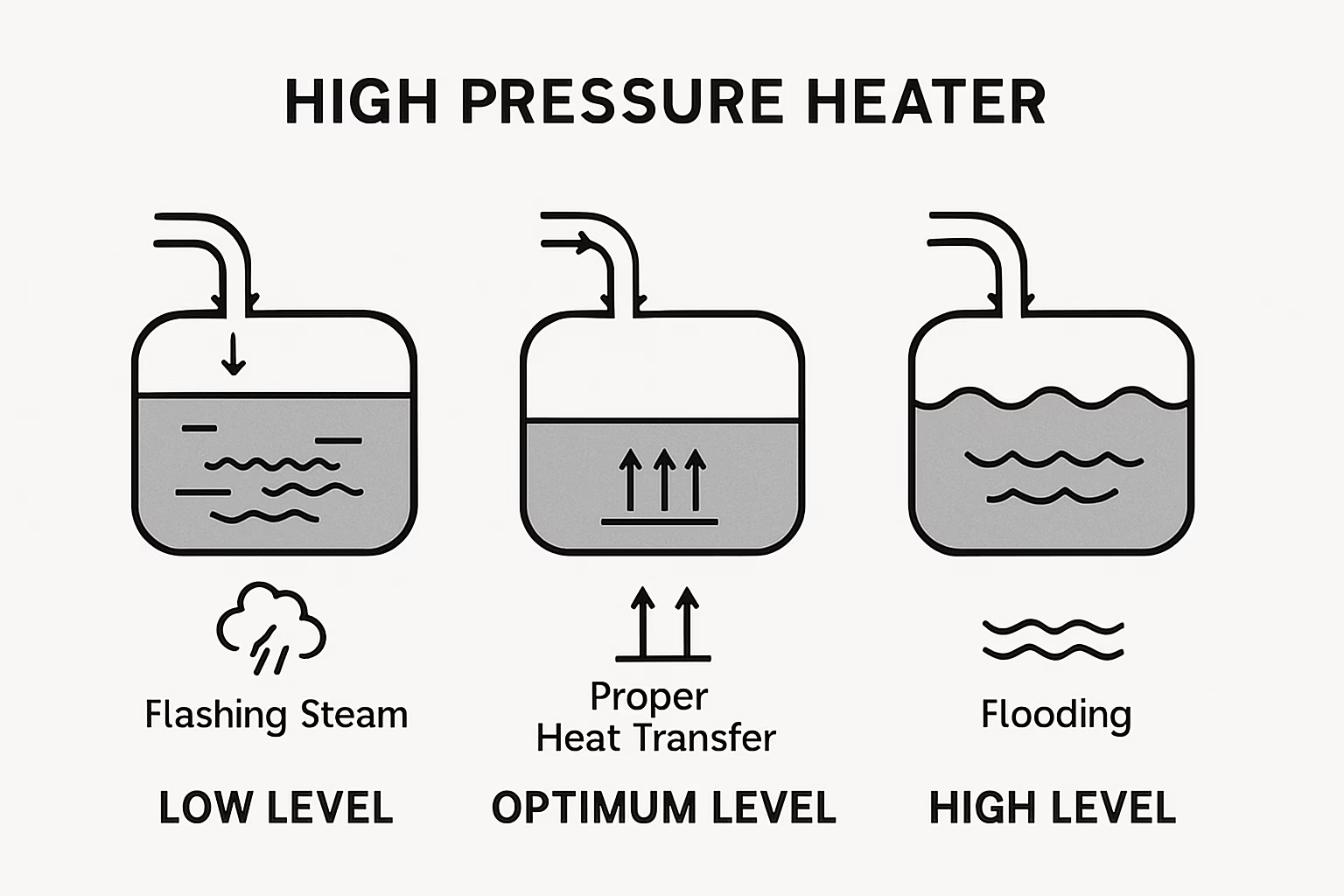

Drip levels refer to the accumulated condensate (drains) level in the heater’s shell, which must be carefully controlled to govern heat transfer and temperature gains. The optimum drip level balances submersion of the drain cooling zone while avoiding flooding of the condensing area, directly affecting metrics like Terminal Temperature Difference (TTD) and Drain Cooler Approach (DCA). Lower TTD and DCA indicate better heat gains, leading to higher feedwater outlet temperatures and improved cycle efficiency.

Effects of Drip Level Variations on HP heaters performance

Maintaining the right drip level is vital for preventing efficiency losses and equipment issues. Here’s how deviations impact performance:

- Low Drip Levels: When levels drop too low, the drain cooling zone becomes exposed, allowing superheated steam to bypass proper cooling. This causes flashing, increases drain temperatures, and reduces overall heat transfer to the feedwater. While DCA may drop initially, it leads to suboptimal temperature gains, tube erosion, and potential leaks from turbulent two-phase flow.

- High Drip Levels: Excessive levels submerge more tubes in condensate, diminishing the effective heat transfer area in the condensing and desuperheating zones. This results in higher TTD and DCA, meaning less heat is absorbed by the feedwater and more is wasted in the drains. Flooding can also increase corrosion risks and force operational adjustments like increased blowdown.

- Optimum Drip Levels for Maximum Heat Gains: The ideal level covers the drain cooler adequately (e.g., around 5-13 inches in tested systems) to enable full subcooling without impeding condensation. This setup minimizes energy losses, prevents flashing, and maximizes feedwater temperature rise. Regular monitoring and adjustments via level control valves can optimize DCA and TTD, potentially improving plant heat rate by recovering heat that would otherwise be lost.

Why Optimum Drip Levels Are Necessary

Proper drip level management ensures good heat gains by enhancing the regenerative process, which raises the average temperature of heat addition in the Rankine cycle. Suboptimal levels can increase fuel use, cause mechanical damage, and reduce plant reliability. For instance, in coal-fired plants, fine-tuning levels during varying loads (e.g., startups or part-load operation) prevents issues like steam hammer or reduced boiler efficiency.

Power plants employ automated controls, alarms, and periodic testing to maintain these levels, often cascading drains to integrate with the overall feedwater system. This not only boosts thermal performance but also supports long-term sustainability by lowering emissions through better fuel efficiency.

Benefits of Optimized HP Heaters in Power Plants

Integrating well-managed HP heaters with precise stage operation and drip level control offers several advantages:

- Enhanced Efficiency: Regenerative heating reduces the heat required from the boiler, cutting fuel costs and improving the plant’s heat rate.

- Equipment Longevity: Balanced levels minimize wear, extending the life of tubes and shells.

- Operational Flexibility: Adaptable to load changes, ensuring stable performance in modern grids with variable renewable integration.

For engineers and plant operators, understanding these elements is key to troubleshooting and optimization. If you’re designing or analyzing power systems, tools like thermodynamic simulations can model these interactions for precise predictions.

This comprehensive guide to high pressure heater stages and drip level management highlights their pivotal role in power plant efficiency. By focusing on these aspects, operators can achieve significant energy savings and reliable operation.

Discover more from WireUnwired Research

Subscribe to get the latest posts sent to your email.