Key Insights

- UBTECH begins mass production of Walker S2 humanoid robots following record $112 million in orders, marking a pivotal shift from prototypes to commercial deployment

- Autonomous battery-swapping technology enables 24/7 continuous operation, reducing downtime and increasing factory productivity in industrial environments

- Phased deployment strategy targets automotive, manufacturing, and logistics sectors across China, with additional $22 million data center contracts signaling broader market expansion

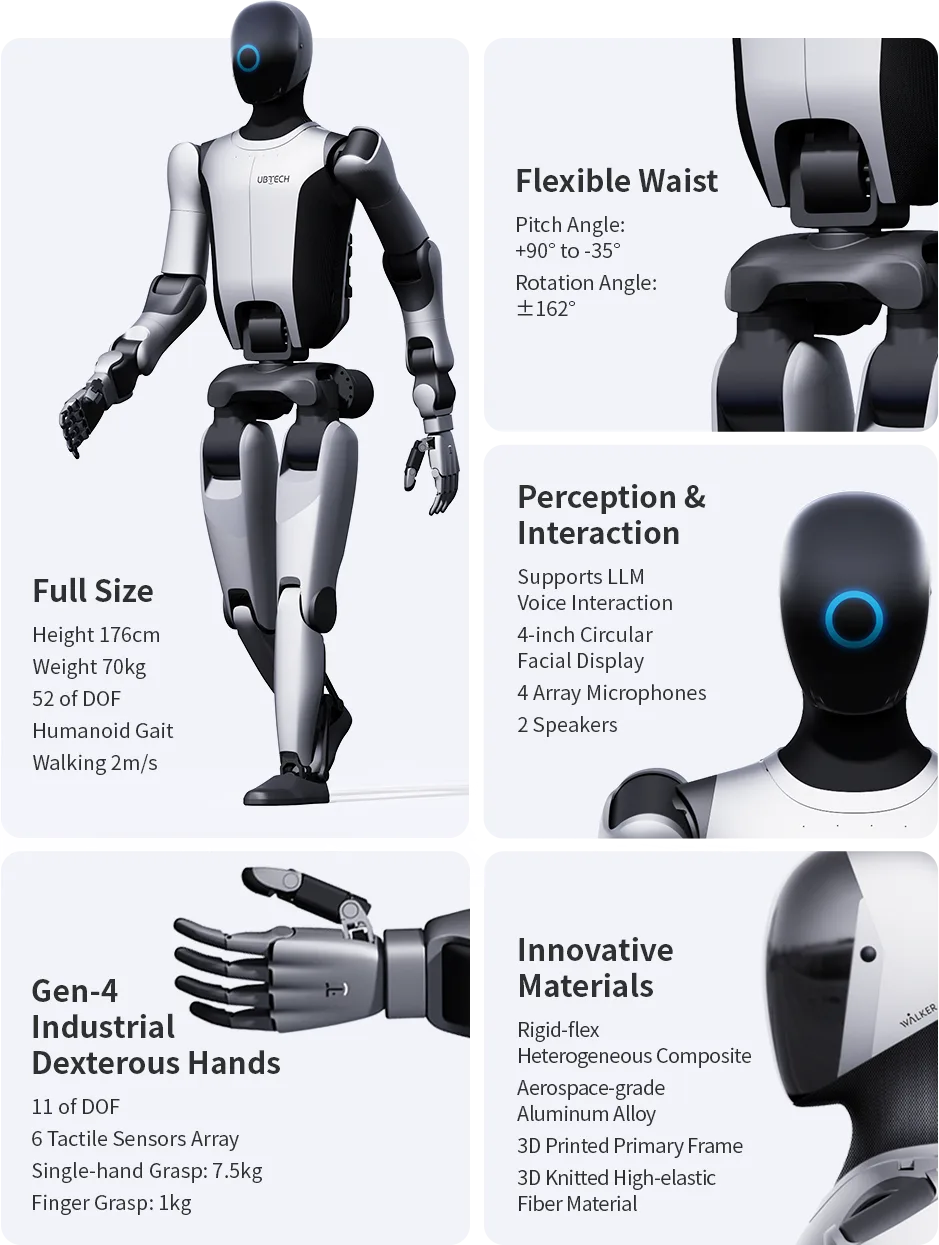

UBTECH has officially entered a new era of industrial robotics by commencing mass production and phased delivery of its Walker S2 humanoid robots, following unprecedented market demand that has generated $112 million in orders. This milestone represents a significant transition from prototype demonstrations to large-scale commercial deployment, positioning the Chinese robotics manufacturer at the forefront of industrial automation innovation. The Walker S2, standing 1.76 meters tall and weighing 43 kilograms, is engineered specifically for round-the-clock factory operations rather than controlled laboratory environments.

The deployment strategy unfolds in phases, with robots being delivered to frontline industrial environments across multiple sectors. Beyond the primary orders, UBTECH has secured an additional $22 million contract for data center operations, indicating that the Walker S2’s capabilities extend beyond traditional manufacturing into emerging technology infrastructure. This dual-track expansion demonstrates market confidence in the robot’s versatility and reliability across diverse operational contexts.

Technical Specifications and Operational Capabilities of Walker S2

The Walker S2’s technical architecture balances mobility, manipulation, and autonomous operation through integrated hardware and software systems. With a maximum walking speed of 7.2 kilometers per hour and typical operational speed of 1 meter per second, the robot navigates factory floors at speeds compatible with human safety standards. Its dual-battery system provides up to 2 hours of active operation between autonomous swaps, and the hot-swap capability eliminates the need for extended charging downtime .

Sensor integration includes dual RGB stereo cameras for vision, depth LiDAR for spatial mapping, a four-microphone array for audio input, 6-axis inertial measurement units in the torso and feet for balance and motion control, and force/tactile sensors in wrists and fingertips for precise object handling. This comprehensive sensor suite enables the robot to perceive its environment with sophistication approaching human sensory capabilities, supporting safe human-robot coexistence on shared factory floors.

The robot’s control system utilizes UBTECH’s BrainNet 2.0 software stack, which integrates vision-based simultaneous localization and mapping (SLAM), real-time path planning, and coordination protocols for multi-robot swarm operations. This architectural approach allows multiple Walker S2 units to work collaboratively, sharing tasks and coordinating movements in complex factory environments. The UBTech Connect mobile and desktop application enables remote status monitoring, task scheduling, and firmware updates, providing factory managers with centralized oversight of deployed units.

What Makes Walker S2 Stand Out in Industrial Settings

The Walker S2 distinguishes itself through a revolutionary autonomous battery-swapping system that fundamentally addresses a critical challenge in industrial robotics: operational downtime. Unlike conventional robots that require manual battery replacement or extended charging periods, the Walker S2 autonomously swaps its dual batteries within approximately three minutes through coordinated dual-arm operations. This capability enables near-continuous 24/7 operation, allowing factories to maximize productivity without the traditional productivity gaps associated with equipment maintenance.

The robot’s physical design incorporates 52 degrees of freedom distributed across its body and arms, enabling human-like mobility and precision manipulation. Its fourth-generation industrial-grade dexterous hands achieve sub-millimeter precision with durability exceeding 80,000 cycles, making it suitable for repetitive assembly tasks, quality inspection, and material handling operations. The Walker S2 can handle payloads up to 15 kilograms within a 1.8-meter workspace and rotate its waist ±162 degrees, providing the flexibility needed for complex factory floor tasks.

Perception capabilities rely on a pure RGB binocular stereo vision system that replicates human-like depth perception as discussed in the technical spec part. This advanced vision technology, combined with real-time path planning algorithms, allows the robot to navigate complex indoor factory environments safely while maintaining awareness of human workers and dynamic obstacles. The integration of UBTECH’s proprietary AI system, known as the Co-Agent stack, enables autonomous task planning, multimodal reasoning, and real-time exception handling without constant human supervision.

Market Impact and Regional Significance of Walker S2

The mass production announcement carries substantial implications for the Asia-Pacific robotics market and reflects China’s growing dominance in humanoid robot commercialization. Regional business media and robotics communities across China and Asia have recognized this achievement as a major leap for local robotics manufacturing, signaling that industrial-grade humanoid robots are transitioning from experimental technology to production-ready solutions. The phased deployment approach suggests UBTECH is carefully managing supply chains and customer integration to ensure successful real-world implementation.

The $112 million in orders, combined with the additional $22 million data center contract, totals $134 million in secured revenue—a remarkable figure that underscores genuine market demand rather than speculative interest. This financial commitment from industrial partners indicates confidence that the Walker S2 delivers measurable return on investment through increased productivity, reduced labor constraints, and improved operational consistency. Automotive manufacturing, general assembly, logistics, and data center operations represent sectors where labor shortages and 24/7 operational requirements create compelling use cases for humanoid robots.

Deployment Strategy and Future Outlook

UBTECH’s phased deployment approach reflects strategic planning to ensure successful integration into existing factory workflows. Rather than flooding the market with simultaneous deployments, the company is methodically delivering robots to partner facilities, gathering operational data, and refining software systems based on real-world performance. This measured rollout reduces implementation risks and allows UBTECH to provide comprehensive support during the critical early adoption phase.

The expansion into data center operations represents a strategic diversification beyond traditional manufacturing. Data centers require 24/7 monitoring, equipment maintenance, and environmental management—tasks where humanoid robots can provide consistent, tireless performance. This market segment offers substantial growth potential as global data infrastructure continues expanding to support artificial intelligence, cloud computing, and digital services.

While global media coverage remains limited to regional and industry-specific outlets as of November 2025, the significance of UBTECH’s achievement resonates strongly within Asia-Pacific robotics communities. The successful transition from prototype demonstrations to mass production validates years of research and development investment, positioning UBTECH as a credible competitor in the emerging industrial humanoid robot market. As manufacturing sectors worldwide grapple with labor shortages and productivity demands, the Walker S2’s capabilities and proven reliability may accelerate global adoption of humanoid robots in industrial settings.

The $112 million in orders and $22 million data center contract represent tangible validation that industrial-grade humanoid robots have achieved commercial viability. UBTECH’s Walker S2 demonstrates that autonomous battery-swapping technology, advanced dexterity, and AI-powered autonomy can combine to create practical solutions for real factory challenges. As these robots enter frontline industrial environments across China, their operational performance will likely influence investment decisions and technology adoption strategies throughout the global manufacturing sector.

Join the conversation: Connect with tech enthusiasts and industry professionals discussing robotics innovations on WireUnwired Research WhatsApp group or engage with our community on LinkedIn for ongoing coverage of industrial automation developments.

Discover more from WireUnwired Research

Subscribe to get the latest posts sent to your email.