Cooling towers are essential structures in a wide array of industrial and commercial applications, from power plants and manufacturing facilities to HVAC systems. Their primary function is to dissipate waste heat into the atmosphere, and the efficiency of this process is significantly influenced by the design and operational principles of the tower. Understanding the different types of cooling towers is crucial for selecting the most suitable option for specific needs. This article delves into the two primary ways cooling towers are classified: by the direction of water and air flow, and by the method of airflow generation.

TRENDING

Classification by Water and Air Flow: Crossflow vs. Counterflow

One of the fundamental ways to differentiate cooling towers is based on how the water and air interact within the tower structure. This leads to two main categories: crossflow and counterflow cooling towers.

cooling tower counter flow induced draftcooling tower counter flow induced draft

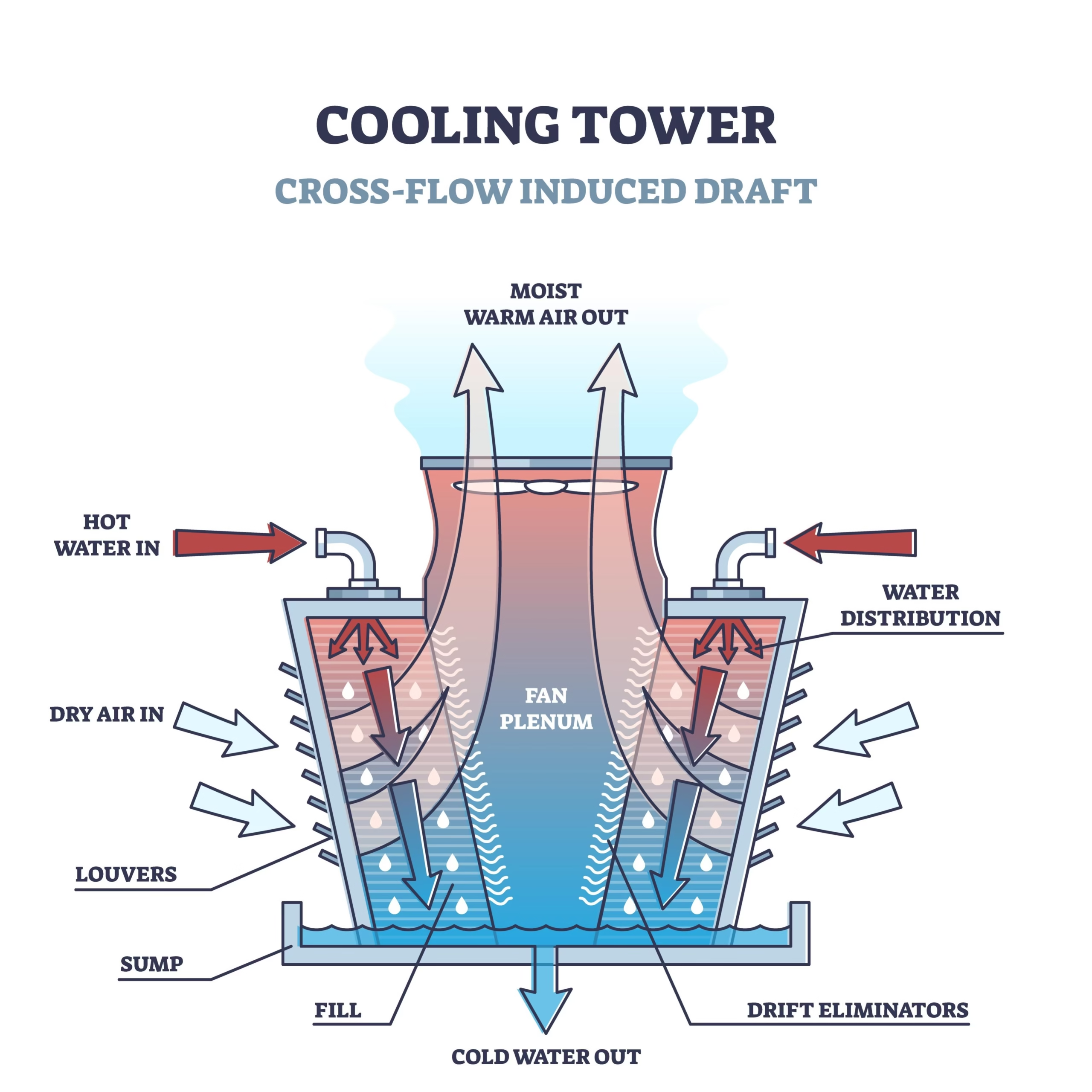

Crossflow Cooling Towers: The Horizontal Dance of Air and Water

In crossflow cooling towers, the air moves horizontally across the falling water. Hot water is distributed through a series of nozzles or basins at the top of the tower and flows downwards through the fill media. Simultaneously, ambient air is drawn horizontally across this falling water stream by fans located on the sides of the tower.

Key characteristics of crossflow towers include:

- Gravity-fed water distribution: This simplifies the pumping system and reduces energy consumption associated with water distribution.

- Large air inlet faces: The open sides facilitate the horizontal movement of large volumes of air.

- Lower air pressure drop: The horizontal airflow path generally encounters less resistance, potentially requiring less powerful fans.

- Easier maintenance access: The open design often provides easier access to the fill and water distribution components.

However, crossflow towers can be more susceptible to freezing in colder climates and may exhibit less efficient heat transfer compared to counterflow designs due to the staged cooling of the air.

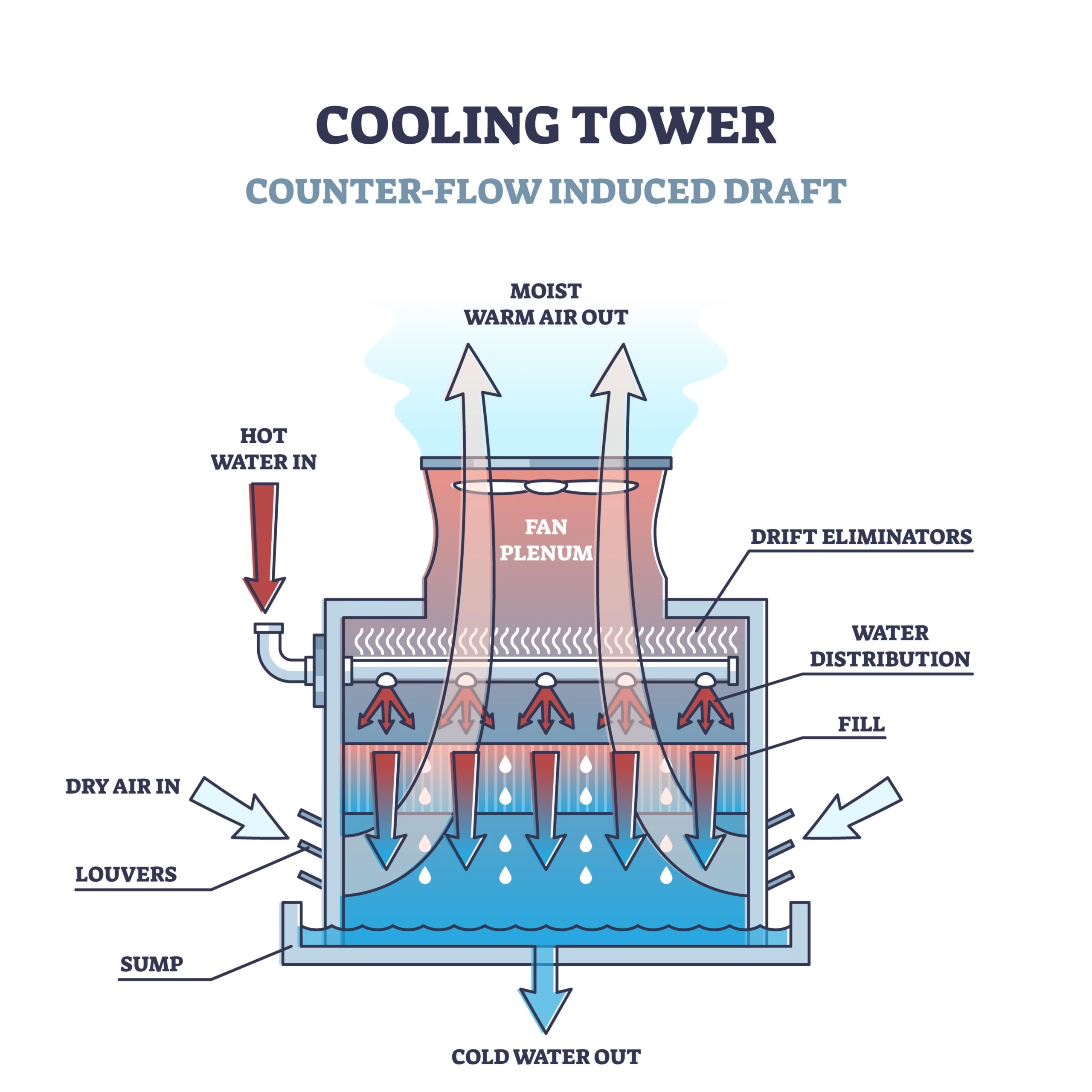

Counterflow Cooling Towers: The Vertical Opposition for Enhanced Heat Transfer

In counterflow cooling towers, the air flows vertically upwards, directly opposing the downward flow of water. Hot water is sprayed downwards through nozzles located at the top of the tower onto the fill media. Fans, typically positioned at the top, draw air upwards through this falling water.

Key features of counterflow towers include:

- Pressurized water distribution: This ensures a more uniform distribution of water over the fill media, enhancing contact with the airflow.

- More efficient heat transfer: The direct counter-current flow allows the coldest incoming air to interact with the coldest outgoing water, maximizing the temperature difference and thus the heat transfer rate.

- Smaller footprint potential: For a given cooling capacity, counterflow towers can often be more compact compared to crossflow designs.

- Reduced recirculation risk: The high exit velocity of the air discharged from the top helps prevent the warm, humid air from being drawn back into the air inlets.

While generally more efficient, counterflow towers might require higher initial pumping head due to the pressurized water distribution system and may present more challenging maintenance access to internal components.

Classification by Airflow Generation: Natural Draft vs. Mechanical Draft

Another crucial way to categorize cooling towers is based on how the air is moved through the tower. This leads to the distinction between natural draft and mechanical draft cooling towers. This classification is independent of whether the water and air flow is crossflow or counterflow.

Mechanical Draft Cooling Towers: Fan-Powered Air Circulation

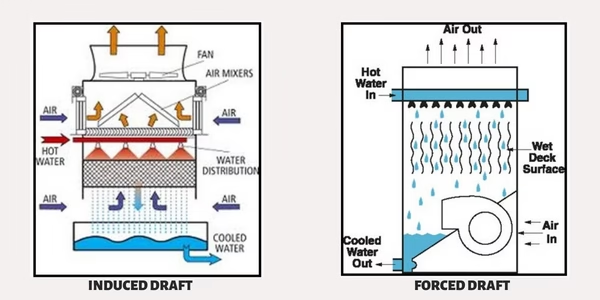

Mechanical draft cooling towers utilize mechanical fans to force or induce airflow through the tower. This provides a more controlled and consistent airflow rate, making these the most common type of cooling towers. They are further subdivided into:

- Forced Draft Cooling Towers: In this design, the fan is located at the air inlet, typically at the base of the tower, and pushes air through the fill media. The air velocity leaving the tower is low. While the fan is accessible for maintenance in the ambient air stream, the low exit velocity can increase the risk of recirculation of the warm, moist discharge air back into the inlet.

- Induced Draft Cooling Towers: This is the more prevalent mechanical draft design. The fan is located at the air outlet, usually at the top of the tower, and pulls air through the fill media. The high exit velocity of the air significantly reduces the likelihood of recirculation, leading to more efficient and stable operation. However, the fan operates in the warm, saturated air stream, potentially requiring more robust materials and maintenance considerations.

Mechanical draft towers offer greater control over cooling performance and are generally more compact than natural draft towers. However, they incur ongoing energy costs for fan operation

Natural Draft Cooling Towers: Harnessing Buoyancy for Airflow

Natural draft cooling towers rely on the principle of natural convection to move air through the tower. These towers are characterized by their large, often hyperbolic shape, which acts as a giant chimney.

- How they work: Warm, moist air inside the tower is less dense than the cooler ambient air outside. This density difference creates buoyancy, causing the warm air to rise and exit the top of the tower. This upward movement of air draws fresh, cooler air into the base of the tower.

Advantages of natural draft towers include:

- Extremely low operating costs: No energy is required for fans.

- High reliability and minimal maintenance: Fewer moving parts compared to mechanical draft towers.

- Low noise levels.

However, natural draft towers also have significant limitations:

- High initial capital cost: The large construction requires substantial investment.

- Large physical footprint: They occupy a significant amount of land.

- Performance is dependent on atmospheric conditions: Cooling efficiency can fluctuate with changes in ambient temperature and humidity.

- Suitable only for very large and relatively constant heat loads, typically found in large power generation facilities.

Conclusion: Choosing the Right Cooling Tower

The selection of the appropriate cooling tower type is a critical decision that depends on a multitude of factors, including the specific application requirements, heat load, available space, environmental conditions, energy costs, and budget. Understanding the fundamental differences between crossflow and counterflow designs, as well as mechanical draft (forced and induced) and natural draft systems, is essential for engineers and facility managers to make informed decisions that optimize cooling efficiency, minimize operational costs, and ensure long-term performance. By carefully evaluating these key differentiations, it’s possible to choose the cooling tower technology that best meets the unique demands of any given application.

Discover more from WireUnwired Research

Subscribe to get the latest posts sent to your email.

Abhinav Kumar

Abhinav Kumar is a graduate from NIT Jamshedpur . He is an electrical engineer by profession and Digital Design engineer by passion . His articles at WireUnwired is just a part of him following his passion.